Isicelo

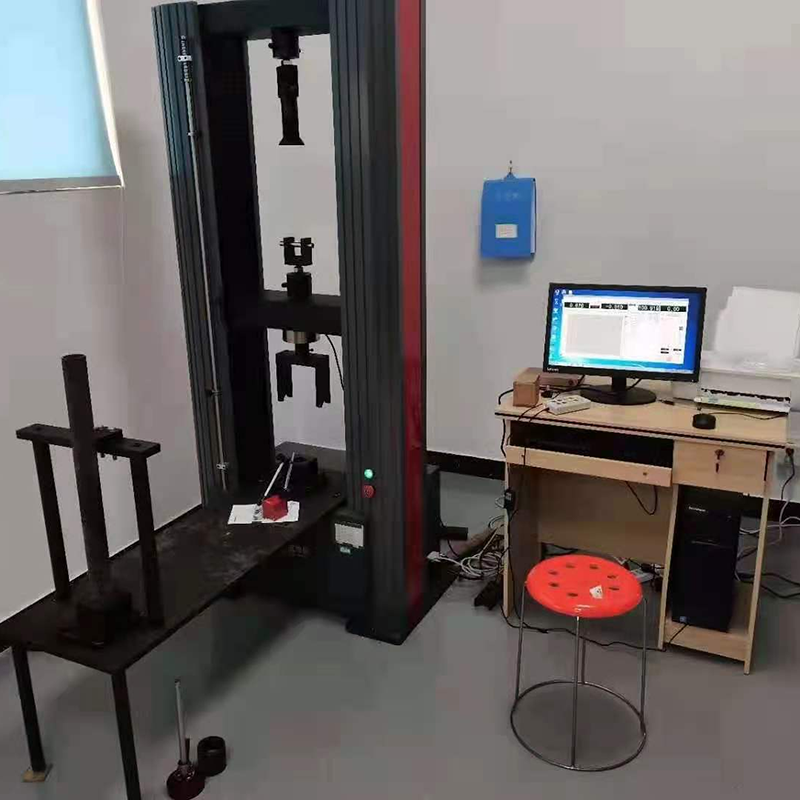

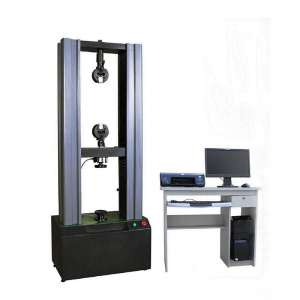

1. I-ZG-L yochungechunge lwe-Microcomputer Retrolped inkinobho yokulawulwa kwe-Bowl kanye nomshini wokuhlola ukuphepha wamukela imiqondo esezingeni eliphakeme, ukubukeka okuhle, ukusebenza okusebenzayo, ukusebenza okuqinile nokuthembekile. Ikhompyutha ilawula ngqo uhlelo lokulawula i-Servo Speed nokujikeleza kwe-servo motor ngokusebenzisa uhlelo lwedijithali oluphelele (ikhadi le-PCI) elakhiwe yinkampani yethu. Ijubane le-AC Servo motor lihlelwe ngohlelo lokukhohlisa futhi lidluliselwa kwisikulufa sebhola le-Screw ukuze liqaphele i-Beam Sukuma, ukuwa, isivivinyo, njll. Isenzo sokuqedela i-Tensile, ukucindezelwa kanye nezinye izakhiwo zemishini zesampula.

2. Isoftware esebenzayo yomshini wokuhlola ingathola ngokuzenzakalelayo i-modulus e-elastic, amandla okuthela, amandla ashukumisayo, amandla okuqina, ukuqina kohlelo lokuqunjelwa, ukuguquguquka kwesampula, i-deformation, Okungahlangabezana nemodi yokulawula evaliwe yokulawulwa kokufuduka okuqhubekayo, ukucindezelwa okungapheli kanye nokuguquguquka okungapheli, futhi inqubo yokuhlola ingahlelwa futhi ilawulwe njengoba kudingwa yileveli. Ukulawulwa kokulawulwa kanye nedatha yenqubo yokuhlola uhlelo lokulawula amakhompyutha kuhlangabezana nezidingo zamazinga ezizwe ahambisanayo ezinto zokwenziwa zensimbi nezinto ezingezona zensimbi, futhi imibiko yokuhlola ihlukene njengezindlela ezinjengegama, nezinye izindlela.

I-3. Lo mshini awunakungcola, umsindo ophansi, ukusebenza kahle okuphezulu, futhi unokulawulwa okuningi kwejubane. Lo mshini ulungele ukuhlola izakhiwo zemishini zezinsimbi ezahlukahlukene, okungezona izinsimbi nezinto ezihlanganisiwe, futhi kuhlangabezana ngokugcwele nezidingo zamazinga ezilo ezizwe afanele.

I-4. Umshini usetshenziswa kabanzi ekuhlolweni kwezinto ezibonakalayo nasekuhlaziyweni kwezinto zokwakha, i-aerospace, ukukhiqiza imishini, ucingo kanye nekhebula, irabhisi namapulasitiki, amasistimu amukelwe. Isetshenziswa ezikhungweni zocwaningo lwesayensi, amanyuvesi, amabhizinisi wezimboni kanye nezimayini, ukugadwa kwezobuchwepheshe, imishini yokuhlola ekahle yokuhlolwa kwezimpahla kanye neminyango yokulamula.

Ukucacisa

| 1 | Amandla aphezulu wokuhlola | I-100kna |

| 2 | Izinga lomshini wokuhlola | 1.0 Iklasi |

| 3 | Ukulayisha uhla | 1% ~ 100% FS (1.0 Class) |

| 4 | Iphutha elihlobene nenkomba | ± 1% (1.0 isigaba) |

| 5 | Ukulungiswa kwe-Test Force |

|

| 6 | Uhla lokulinganisa lwe-Deformation | 0.2% ~ 100% |

| 7 | I-Force Control Control Rate Range | 0.005% ~ 5% FS / s |

| 8 | I-Force Control Rate Control ukunemba | Ukukala <0.05% FS, ± 1%;

|

| 9 | Uhla lokulungiswa kwesilinganiso se-Defformation | 0.005 ~ 5% fs / s; |

| 10 | Ukunemba kokulawula isilinganiso sokulawula | Ukukala <0.05% FS / S, ± 1%; I-Rage≥0.05% FS / S, ± 0,5%; |

| 11 | Uhla lokulungiswa kwezilinganiso |

|

| 12 | Ukungena kwezinga lokulawula isilinganiso | ± 0.2%; |

| 13 |

| 0.5% ~ 100% FS |

| 14 | Amandla ahlala njalo, i-deformation njalo, ukunemba okulawulwa njalo |

|

| 15 |

| I-400mm |

| 16 | Ukuhlukaniswa phakathi kwezinsimbi eziphezulu neziphansi | I-650mm |

| 18 | amandla kagesi | ~ 220v ± 10 50hz |

| 19 | Isisindo somshini | I-500KG |

Izici ezibalulekile

1. Umshini wokuhlola awunakungcoliswa, umsindo ophansi, ukusebenza okulula nokusebenza okuphezulu;

2. Umshini omkhulu we-Shell wamukela i-aluminium alloy igobolondo, enhle futhi enomusa;

I-3. Iyunithi eliphambili liyisakhiwo esimile esimile, ngokuqina okuqinile, ukusebenza okuzinzile nokubukeka okuhle;

I-4. Ukwelula nokucindezelwa kutholwa ngezindawo ezihlukene eziphindwe kabili, ukugwema ukuqina kokubuyisela okunamathiselwe okuhlukile kokuhlolwa endaweni efanayo;

I-5. Isakhiwo segama eliyinhloko siqinile futhi siqinile. Isikulufa sebhola eliminyene futhi siqondise induku ekhanyayo, ugongolo olugqinsiwe bese kusekela ifreyimu eqinile, engahlangabezana nokuhlolwa kwezinto ezinamandla amakhulu;

I-6 Lapho kwenziwa isivivinyo se-axial, ukuqinisekisa ukuthi amandla alandelayo esampula ngaphansi komthwalo athinteka kancane, futhi izingcindezi ezinembile kanye nemiphumela ye-strain zingatholakala. ;

7 I-coefficle eyanele yesikulufa isikulufa incane, ukusebenza kahle okudlulayo kuphezulu, ukunemba kuphakeme, namandla aphezulu;

8. Indlela yokuncipha eyakhiwe ngebhande le-reducer, ibhande elihlanganisiwe le-synchronous, kanye ne-pair ye-screw ye-screcision enembile inesakhiwo esilula sokuqinisekisa ukunyakaza okuvumelaniswa kwesikulufa futhi kusize uhlelo lube isikhungo;

9 Kuyinto eqondile ye-modulus nenani lezinhlangu. Isebenza ngokukhethekile lapho ihlola izinto ezinamandla aphezulu, njengezinto zokwakha ze-aerospace nezinhlanganisela zensimbi;

10. Usebenzisa uhlelo lokulawula imoto ye-AC servo motor kanye nesivinini sokulawula inqubo yokuhlola, ukunemba kokulawula kuphezulu, okuzinzile, ukusebenza kahle, umsindo ophansi (ijubane eliphansi

Ngokuyisisekelo akukho msindo ngaleso sikhathi). Futhi uhla lwejubane lokulawula lunwetshwe kakhulu (0.001-500mm / min), okungazuzisi kuphela ekuhlolweni okusheshayo kwezinto ezijwayelekile zezinto ezijwayelekile (insimbi, usimende, ukhonkolo, njll.), Kepha futhi nokuhlolwa okusheshayo kwejubane Izinto ezingezona zensimbi (irabha, ifilimu, njll.). Kuyinto elula ukuguqula ngokushesha isikhala sokuhlola lapho kungekho umthwalo, bese ugcine isikhathi sokuhlola esizayo. Ijubane lokuhlola lihlangabezana nezidingo zamanje zesivinini sokuhlola sazo zonke izinto zensimbi ezijwayelekile nezingezona zensimbi eChina;

11. I-Multi-precification adapters kanye nezinketho eziningi zokutholwa kwezinto ezingabona ukuhlolwa kwemishini kwezinhlobo ezahlukahlukene, okunikeza imishini imisebenzi yokuhlola eyengeziwe;

12. Indandatho egxilile kanye nokubeka isikhonkwane kuqinisekisa ngokugcwele ukuqaqamba okuphezulu nangaphansi kwesimo sokuhlola, ukuze i-specimen igcizelelwe ngokuphelele ekuqondisweni kwe-axial;

13 Ngemuva kokulinganisa okungahleliwe, isivivinyo asithintwa amabutho angaphandle, esingaqinisekisa ukunemba kwenqubo yokuhlola namapharamitha;

14. Ukuqondiswa kwamandla kwenzwa kuyafana ngesikhathi kuqhubeka isikhathi eside, ukucindezela kanye nezinye izivivinyo, kanye nokulinganiswa nokulinganisa kulula futhi kulula;

15. Izinzwa zezinzwa ezihlukile zingalungiswa ngokuya ngezidingo, ezandisa kakhulu uhla lokuhlola lokuhlangabezana nezidingo zokulinganisa zemithwalo ehlukene yokuhlola;

16. Ukulinganiswa kwe-defformation kwamukela ukunemba okuphezulu nge-elektroniki ye-electronic noma i-deformation enkulu exclowsometer;

17. Ukulinganiswa okuxoshwa kutholakala ngohlelo lokulinganisa owakhelwe ngaphakathi kwe-AC Servo Motor;

18. Ukulawulwa okukude okungenantambo okuphephile kuhlanganisa ngobuhlakani imisebenzi eminingi, elula kakhulu ukuyisebenzisa nokusebenza, futhi yenza lula ukucushwa okuqinile kwamanje, kunciphise ukusetshenziswa kwezinga elikagesi le-discrete, futhi kunciphise ngempumelelo izinga lokuhluleka kagesi;

19. Ungabona ukulungiswa okusheshayo / okuhamba kancane kokuphakamisa ugongolo lapho i-specimen iboshwe, futhi ukusebenza kuyashintshashintsha futhi kungashintshwa ngentando;

20. Unomsebenzi wokubuyela esimweni sokuqala ngemuva kokuhlolwa, okusebenzayo futhi okusheshayo;

21. Inomsebenzi ophelele wokuvikelwa komkhawulo, ukugcwala ngokweqile kanye nokuvikelwa okuphezulu, ukuvala ukuvala okuzenzakalelayo neminye imisebenzi, ethembekile futhi ephephile;

22 kanye nokuqina kwezinga eliqhubekayo. Futhi ingabona ukushintsha okubushelelezi phakathi kwezindlela ezahlukahlukene zokulawula ngaphandle kokuphazamiseka;

23. Uhlelo lokulinganisa nokulawula luhlome ngephakeji yesoftware yokuhlola imisebenzi eminingi, futhi yamukela ubuchwepheshe bokutholwa kwedatha ephezulu kwedatha ukufezekisa ukutholwa okusheshayo kwemininingwane ye-multine yesiteshi; Imiphumela yokuhlola ingahlaziywa futhi icutshungulwe ngokuya ngezidingo zezindlela ezahlukahlukene zokuhlola, futhi umsebenzi wokulawula wokuhlela owenziwe womuntu unikezwe ukwenza lula ukwengeza izivivinyo ezintsha. Okujwayelekile; Inemisebenzi yokusebenza enamandla ye-Graphics, ingabonisa amajika okuhlola kanye nedatha yokuhlola ngesikhathi sangempela, inezifiso zokusondeza, ukusondeza imidwebo, imisebenzi yokuqonda, kanye nesikhombisi kulandela imisebenzi yokubonisa. Inomsebenzi wokugcina wama-curve aphelele wokuhlola nedatha yokuhlola; Inemisebenzi yokukhishwa kombiko owodwa wokuhlola iziqu zokuhlola kanye nokuphrinta kokukhishwa kweBatch Test.

24. Nge-interface yenethiwekhi, ingabona amanethiwekhi wedatha kanye nemisebenzi yokulawula kude;

25. Imishini isebenza ngeyakha. Izinga lemishini engenisiwe, intengo yemishini yasekhaya.

-Vamile

1. I-GB / T228-2002 "I-Metal Materiment Igumbi Lokushisa Tensile Test"

2. I-GB / 15831-2006 I-Scaffolding Fasteners

3. I-GB / T5725-2009

4. I-GB / T15831-2006 "I-Steel Pipe Scaffolding Fasteners"

I-5. I-GB2491112010110

I-6. I-GBT 6096-2009-2009 I-Belt Belt Test Indlela, i-GB 5725-2009 Inetha Lokuphepha namanye Amakhulu Amazinga, kanye nezindlela ezijwayelekile zingenziwa ngezifiso zabasebenzisi.