Isicelo

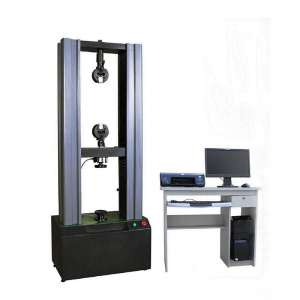

Lo mshini we-20kn Computer spring tension and compression tester/spring tester wakhiwa futhi ukhiqizwa yinkampani yethu, esetshenziswa kakhulu ukuhlola amandla azo zonke izinhlobo zama-valve springs kanye nezingxenye zokunwebeka.I-50kn I-computer spring tension kanye ne-compression tester/spring tester ingakala amandla okuhlola engxenye yentwasahlobo ne-elastic ngaphansi kwe-deformation ethile noma ukuphakama okusele, futhi ingakala ukuphakama okusele noma ukuguqulwa kwengxenye yentwasahlobo nokunwebeka ngaphansi kwamandla athile okuhlola.Umshini wokuhlola uyathuthukiswa futhi ukhiqizwe ngokuvumelana nezidingo ze-JB/T7796-2005 Tension kanye nemishini yokuhlola intwasahlobo yokucindezela.

Ukucaciswa

| Amandla okuhlola aphezulu | 20kN |

| Ibanga lokulinganisa amandla okuhlola | 2%~100% |

| Ukunemba kokulinganisa kwamandla okuhlola | okungcono kuno-± 0.5% yenani elibonisiwe |

| Ukulungiswa kokususwa | 0.001mm |

| Ukunemba kwesilinganiso sokususwa | ± 0.5% |

| Iphutha elihlobene lenani lenkomba yokuguquguquka | ngaphakathi± 0.5% |

| Ukulungiswa kokuguqulwa | 0.001mm |

| Iphutha elihlobene lezinga lokulawula amandla | ngaphakathi ± 1% yenani elimisiwe |

| Ibanga lokulinganisa le-Crossbeam | 0.001 ~200mm/min; |

| Isikhala esiqinile | 0 ~ 600mm |

| Indawo yokucindezela | 0 ~ 600mm |

| Ubuningi bokuhamba kwe-crossbeam | 600mm |

| Ukunikezwa kwamandla kagesi | 220V 50Hz |

Izici Eziyinhloko

1. Umsingathi:Umshini wamukela isakhiwo somnyango onesikhala esikabili, indawo engaphezulu iyeluliwe, futhi indawo ephansi iyacindezelwa futhi igobile.I-beam iphakanyiswa ngaphandle kwesinyathelo futhi yehliswe.Ingxenye yokudlulisela isebenzisa ibhande eliyindilinga le-arc synchronous toothed, ukudluliswa kwepheya yesikulufu, ukudluliswa okuzinzile nomsindo ophansi.Isistimu yokunciphisa ibhande elinamazinyo aklanywe ngokukhethekile kanye nokupheya kwesikulufa sebhola okunembayo kushayela ugongolo olunyakazayo lomshini wokuhlola ukuze uthole ukudluliswa okungahlehla emuva.

2. Izinsiza:

Ukucushwa okujwayelekile: isethi eyodwa yokunamathiselwa kwengcindezi okumise okukaweji nokunamathiselwe kokuminyanisa.

3. Isistimu yokulinganisa nokulawula kagesi:

(1) Yamukela isistimu ye-servo ye-TECO AC kanye ne-servo motor, esebenza kahle futhi enokwethenjelwa, ene-over-current, over-voltage, over-speed, overload nezinye izisetshenziswa zokuvikela.

(2) Inemisebenzi yokuvikela efana nokugcwala ngokweqile, amandla amanje, amandla kagesi angaphezu kwavamile, imikhawulo ephezulu nephansi yokugudluka kanye nokuma kwesimo esiphuthumayo.

(3) Isilawuli esakhelwe ngaphakathi siqinisekisa ukuthi umshini wokuhlola ungafinyelela ukulawulwa kwe-loop evaliwe yamapharamitha njengamandla okuhlola, ukuguqulwa kwesampula nokugudluzwa kwe-beam, futhi angakwazi ukuzuza amandla okuhlola isivinini esingaguquki, ukugudluzwa kwesivinini okungaguquki, isivinini esiqhubekayo, isivinini esingaguquki. umjikelezo womthwalo, Ukuhlolwa okufana nemijikelezo ye-velocity deformation engashintshi.Ukushintsha okushelelayo phakathi kwamamodi okulawula ahlukahlukene.

(4) Ekupheleni kokuhlolwa, ungakwazi ukubuyela ngesandla noma ngokuzenzakalelayo endaweni yokuqala yokuhlolwa ngesivinini esikhulu.

(5) Qaphela ukulungiswa kwangempela kwe-zero ngokomzimba, ukulungiswa kokuthola, kanye nokuguquguquka okuzenzakalelayo, ukulungiswa kwe-zero, ukulinganisa nokugcinwa kwesilinganiso samandla okuhlola ngaphandle kwanoma yiziphi izixhumanisi zokulungisa i-analog, futhi isifunda sokulawula sihlanganiswe kakhulu.

(6) Isifunda sokulawula ugesi sisho izinga lamazwe ngamazwe, elihambisana nendinganiso kagesi yomshini kazwelonke wokuhlola, futhi inekhono eliqinile lokulwa nokuphazamiseka, eliqinisekisa ukuzinza kwesilawuli kanye nokunemba kwedatha yokuhlola.

(7) Inokuxhumana kwenethiwekhi, okungakwazi ukwenza ukudluliswa kwedatha, ukugcinwa, amarekhodi okuphrinta kanye nokudluliselwa kwenethiwekhi nokuphrinta, futhi ingaxhunywa kunethiwekhi yangaphakathi ye-LAN noma ye-Inthanethi yebhizinisi.

4. Incazelo yemisebenzi eyinhloko yesofthiwe

Isofthiwe yokulinganisa nokulawula isetshenziselwa imishini yokuhlola i-electronic universal elawulwa yi-microcomputer ukuze yenze izivivinyo ezihlukahlukene zensimbi nezingezona ezensimbi (njengamaphaneli asekelwe ngokhuni, njll.) futhi iqedele imisebenzi ehlukahlukene njengokulinganisa kwesikhathi sangempela nesibonisi, okwangempela. -ukulawula isikhathi kanye nokucutshungulwa kwedatha, kanye nomphumela ophumayo ngokuhambisana namazinga ahambisanayo.

(1) Ukuphathwa kwegunya elihlukene.Abaqhubi bamazinga ahlukene banegunya lokusebenza elihlukile, futhi okuqukethwe kwamamenyu asebenzayo nakho kuhlukile, okwenza umsebenzi ube lula, ulungele futhi usheshe kuma-opharetha ajwayelekile, futhi ivikele ngempumelelo uhlelo;

(2) Ukulinganisa kwesikhathi sangempela kanye nokuboniswa kwamandla okuhlola, inani eliphakeme kakhulu, ukugudluka, ukuguqulwa nezinye izimpawu;ukutholwa nokulawula kwesikhathi sangempela ngaphansi kwamapulatifomu emodi ye-NT njengeWin2000 neWinXP;kanye nesikhathi esinembile kanye namasampula anesivinini esikhulu;

(3) Ukuboniswa kwesikrini sesikhathi sangempela samajika okuhlola ahlukahlukene njengokuwohloka komthwalo, ukususwa komthwalo, njll., kungashintshwa futhi kubhekwe nganoma isiphi isikhathi, futhi kulula kakhulu ukusondeza noma ukuphuma ejikeni;

(4) Ukugcinwa kwekhompyutha, ukusetha, ukulayisha kanye neminye imisebenzi yemingcele yokuhlola, ukulungisa iqanda, ukulinganisa kanye neminye imisebenzi konke kwenziwa ku-software, futhi ipharamitha ngayinye ingagcinwa futhi idluliselwe kalula, ukuze umsingathi oyedwa ahlonyiswe izinzwa eziningi.Ukushintsha okulula, futhi akukho mkhawulo enanini;

(5) Ukusekela izindlela ezihlukahlukene zokulawula, okuhlanganisa i-open-loop ye-open-loop ye-velocity engaguquki kanye namandla esivinini angashintshi, ukucindezeleka kwesivinini esiqhubekayo nezinye izindlela zokulawula i-loop evaliwe;futhi inikeze ijika elijwayelekile lereferensi lapho u-opharetha othuthukile elungisa amapharamitha weluphu evaliwe, ukuze abasebenzisi bakwazi ukubona umthelela wepharamitha ngayinye kumphumela weluphu evaliwe.

(6) Uhlelo lochwepheshe lokusetha okuhlakaniphile kwamamodi okulawula inqubo yokuhlola lunikezwa abasebenzisi abangochwepheshe abanabahleli bohlelo abazenzakalelayo.Abasebenzisi bangahlanganisa ngokuguquguqukayo izindlela zokulawula eziningi futhi balawule isivinini ngokuya ngezidingo zangempela futhi bahlanganise izinhlelo zokulawula ezifanelana nezidingo zabo.Isofthiwe yokulinganisa nokulawula izolawula ngokuzenzakalelayo inqubo yokuhlola ngokuya ngezilungiselelo zomsebenzisi.

(7) Hlaziya idatha ngokusebenzisa ukuxhumana komuntu namakhompyutha.Indlela yokucubungula ihlangabezana nezidingo ze-"GB/T 228-2002 Room Temperature Tensile Test Method for Metallic Materials" esetshenziswa kabanzi, engakwazi ukubala ngokuzenzakalela amapharamitha ahlukahlukene okusebenza njengemodulus enwebekayo, amandla esivuno, amandla okunweba ashiwo angalingani, futhi ukungenelela okwenziwa ngesandla enqubweni yokuhlaziya., Thuthukisa ukunemba kokuhlaziya;okunye ukucutshungulwa kwedatha nakho kungenziwa ngokuya ngamazinga anikezwe umsebenzisi.

(8) Idatha yokuhlola igcinwa kumafayela ombhalo ukuze kube lula imibuzo yabasebenzisi, nokusebenzisa noma yimiphi imibiko yebhizinisi evamile kanye nesofthiwe yokucubungula amagama ukuze kucutshungulwe kabusha idatha yokuhlola, nokwenza lula ukudluliswa kwedatha ku-inthanethi;

(9) Ingarekhoda futhi ilondoloze ijika ledatha layo yonke inqubo yokuhlola, futhi inomsebenzi wokubonisa ukuze ibone ukukhiqizwa kabusha kwejika lokuhlola.Kungenzeka futhi ukuphakamisa futhi uqhathanise ama-curves ukuze kube lula ukuhlaziywa okuqhathanisayo;

(10) Umbiko wokuhlola ungaphrintwa ngendlela edingwa umsebenzisi.Abasebenzisi bangakhetha ukubika nokukhipha ulwazi oluyisisekelo, imiphumela yokuhlolwa nokuqukethwe kwejika lokuhlola ngokwabo ukuze bahlangabezane nezidingo ezihlukahlukene;

(11) Ukulungiswa kwe-Digital zero kanye nokulinganisa okuzenzakalelayo kwamandla okuhlola kanye nokuguqulwa kuyabonakala, okwenza kube lula ukusebenza futhi kuthuthukise ukuthembeka komshini.Izilungiselelo zesistimu yepharamitha ehlukahlukene zigcinwa ngendlela yamafayela, okulula ukuwagcina nokubuyisela;

(12) Ingasetshenziswa ezinhlelweni ezahlukene zokusebenza ezifana Win98, Win2000, WinXP.Ukulawulwa kwenqubo yokuhlola, uguquko lwejubane lokuhamba kwe-beam, okokufaka kwepharamitha nokunye ukusebenza konke kungaqedwa ngekhibhodi negundane, okulula nokushesha ukulisebenzisa;

(13) Ingakwazi ukukhomba ngokuzenzakalelayo futhi isekele ukulawulwa kwe-jog yangaphandle, ikwenze kube lula ukubopha isampula;

(14) Inomsebenzi wokuvala shaqa okuzenzakalelayo ukuze kuvikelwe ukulayisha ngokweqile, futhi inganquma ngokuzenzakalelayo ukuthi isampula iphukile futhi ivalwe ngokuzenzakalelayo.

Ngokwezidingo ezihlukene zabasebenzisi, imisebenzi yesofthiwe engenhla ingase ikhuliswe noma yehliswe noma ilungiswe.

5. Isikhombikubona sokusebenza kwesofthiwe nesofthiwe:

(1)Isofthiwe ingaba ku-Windows98/2000/XP, futhi okusetshenziswa kubonwa kuveza isistimu yewindi yesiShayina/yesiNgisi ehambisana nesitayela seWindows.

(2) Izindlela zokulawula eziningi zingakhethelwa ukulawula uhlelo oluzenzakalelayo.

(3) Uhlelo oluzenzakalelayo lochwepheshe abahlakaniphile abalawulwa uhlelo.Izinyathelo ezifika kwezingu-50 zingahlelwa ngokuzenzakalelayo.

(4)Bika ukuhlela

(5) Kunezinhlobo eziningi zezindlela zokuhlola, ozikhethela

(6)Isofthiwe inamazinga amathathu esiphathimandla sokuphatha, angenwe ngemvume ngamaphasiwedi awo afanele, aphinde aqinisekise ukusetshenziswa okuphephile kwesofthiwe.

Okujwayelekile

Ihlangabezana nezimfuneko kazwelonke ejwayelekile ye-GB/T228.1-2010 "Metal Material Tensile Test Method at Room Temperature", GB/T7314-2005 "Metal Compression Test Method", futhi ihambisana nokucutshungulwa kwedatha ye-GB, ISO, ASTM , i-DIN namanye amazinga.Ingakwazi ukuhlangabezana nezidingo zabasebenzisi kanye namazinga anikeziwe.