Isicelo

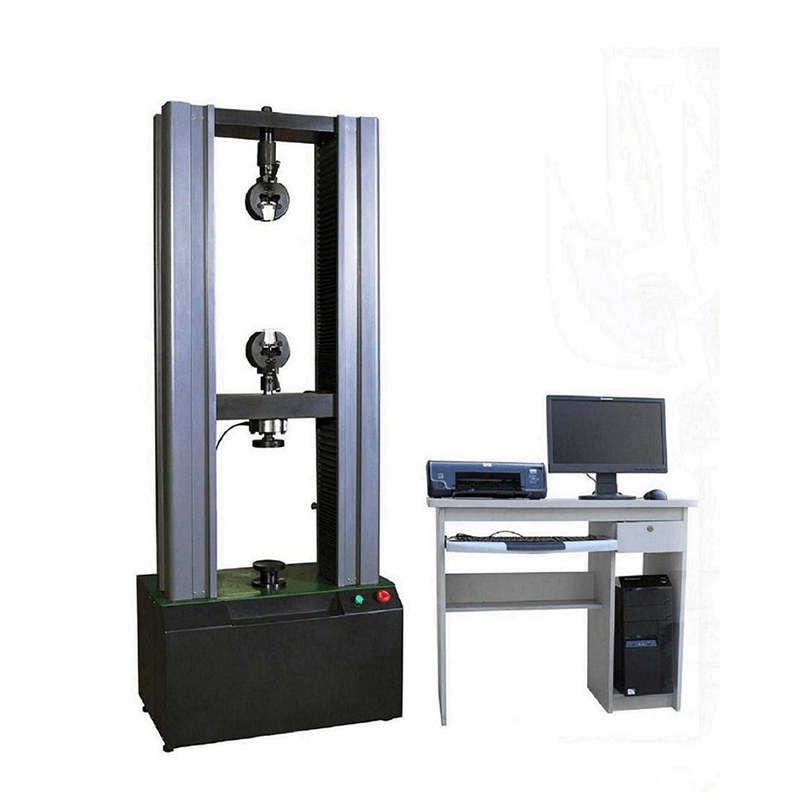

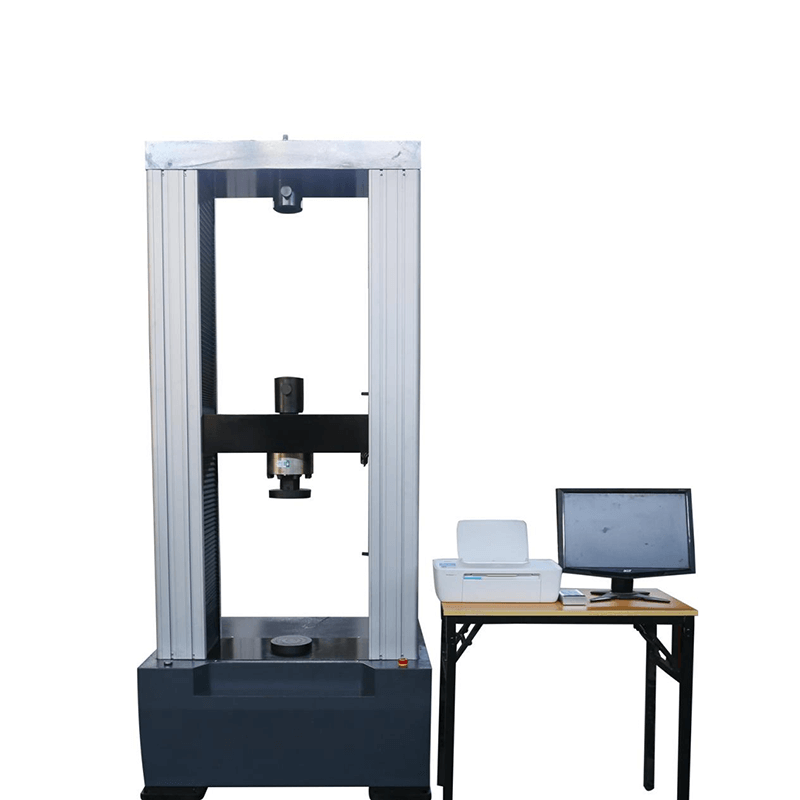

Le mishini yokuhlola ifakwe ikhompyutha, iphrinta, ne-general test software, ukunikeza inqumo enembile ye-metal mandla athe xaxa, amandla okuthela, izinhlinzeko zamandla angelula angeyona, e-elongastic modulus mechicals. Imiphumela yokuhlola ingaphrinta (Force - Ukuchithwa, amandla - Ukuchithwa, ukucindezelwa - Ukuchitheka, ukucindezelwa - Ukuchitheka, isikhathi) umsebenzi wokuzihlola we-software ongakubona ubona izinkinga zokuzihlola . Kuyinto engcono yokuhlola imishini yamabhizinisi wezimboni kanye nezimayini, amayunithi wokucwaninga wesayensi, amanyuvesi, isiteshi sokugadwa kwekhwalithi yobunjiniyela. Ziyingxenye yokuhlola ikhwalithi yekhwalithi ephezulu yephrojekthi yephrojekthi, amanyuvesi kanye namakolishi, isikhungo sokucwaninga nezimboni nezimayini.

Ukucacisa

| Khetha imodeli | WDW-50D | WDW-100D |

| Amandla aphezulu wokuhlola | I-50Kan 5 Tons | I-100KN 10TONS |

| Izinga lomshini wokuhlola | 0.5 Izinga | |

| Ibanga lokulinganisa amandla wokuhlola | 2% ~ 100% FS | |

| Iphutha elihlobene nenkomba ye-Test Force | Ngaphakathi ± 1% | |

| Iphutha elihlobene nenkomba yokufudumala | Ngaphakathi ± 1 | |

| Isinqumo Sokususa | I-0.0001mm | |

| Uhla lwe-Beam Special Ukulungiswa | I-0.05 ~ 1000 mm / min (ilungiswe ngokunganqikazi) | |

| Iphutha elihlobene nesivinini se-beam | Ngaphakathi kwe- ± 1% yenani elisethiwe | |

| Isikhala Esinempumelelo Sokungezelela | Imodeli ejwayelekile ye-900mm (ingenziwa ngokwezifiso) | |

| Ububanzi bokuhlola obusebenzayo | Imodeli ejwayelekile engu-400mm (ingenziwa ngokwezifiso) | |

| Ubukhulu | 720 × 520 × 1850mm | |

| I-Servo motor control | 0.75kw | |

| ukunikezwa kwamandla kagesi | 220v ± 10%; I-50hz; 1kw | |

| Isisindo somshini | 480kg | |

| Ukucushwa okuyinhloko: 1 Ukulungiswa okungejwayelekile kungenziwa ngokwezifiso ngokuya ngezidingo zesampula yamakhasimende. | ||

Izici ezibalulekile

1.Uhlaka oluqinile lokuma phansi luyakha isakhiwo ngendawo ephezulu yeTensile neyephansi ngokucindezela kanye nokuhlolwa kokugoba

2.Izikulufa zebhola eziqondile zimelana nokulayishwa konke ngokusetshenziswa kwesikhathi eside kanye nesakhiwo esihlangene.

3.Uhlelo lokulawula isivinini lusethwe ngaphansi kwetafula futhi luqukethe ibhande elihlanganisiwe le-tooned kanye ne-pulley lokudlulisela kahle, okufakwe ngomsindo ophansi nokunakekelwa kwamahhala.

4.I-crossbeam elungisiwe njengezinhlaka, futhi ihlala ngenhla kohlaka nangomugqa ophakathi nendawo ephakathi nendawo yokulayisha ngokuhamba kahle lapho uhlola. Inzwa yokunemba okunembazo ephezulu ifakiwe ngaphansi kwe-crossbeam.

5.Layisha ngokuzenzakalelayo ukubekezelela ,, ukucindezela, ukulawulwa kwezinhlangu, ukulawulwa komjikelezo kanye nohlelo lokuzihlela.

6.Inzwa ephezulu yokuthathwa komthwalo wesilinganiso esinembile nesizinzile

7.Isivinini sokuhamba esibanzi sokuhamba kusuka ku-0.05 ~ 500mm / min

8.Ukuvikelwa okugcwele ngokweqile: Njengoba amandla okuhlola adlula ama-2% -5% wamandla wokuhlola aphezulu wefayela ngalinye, ukuvikelwa okulayishwa ngokweqile, kuzoma.

-Vamile

ASTMA370, ASTME4, ASTME8, ASTME9, ISO6892, ISO7438, ISO7500-1, i-GBT2, GBT3491-230-1991, I-GB6349-1986, GB / T 1040.2-2006, ASTM C165, EN826, EN1606, EN1607, EN1430 njll.