Inkambu yesicelo

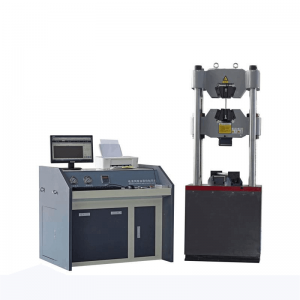

Lo chungechunge umshini wokuhlola wokuhlola u-Utm owenzelwe ukuboniswa kwe-PC kanye nohlelo lokulayisha lwe-hydraulic lwe-hydraulic, isilawuli esikhulu se-enjini silungiswa ngokwehlukile. Inezici zokusebenza kokusebenza, ukusebenza ngokuqinile, ukunemba okuphezulu nokulayisha okuqinile. Kusetshenziselwa ukwelula, ukucindezela, ukugoba nokusika usimende wensimbi, ukhonkolo, amapulasitiki nokunye.

Izici ezibalulekile

Ithangi eli-1 likaphethiloli lifakwe ngaphansi komgcini, isikhala sokuhlola se-Tensile sitholakala ngenhla komgcini, ukucindezela, ukugoba, isikhala sokuhlola sokugunda, ukufuya, isikhala sokuhlola esisezingeni eliphezulu sitholakala ngaphansi komsingathi, kusho phakathi kogongolo.

2 Lesi sakhiwo senzelwe ngekholamu ezine esiqinile kanye nesikulufo ezimbili, wonke umshini unokuzinza okuqinile.

3 Umgcini wenzelwe konke - ngokungenanhloso ukuqinisekisa ukuqina kwawo okuqinile kakhulu ukuze akwazi ukumelana nodoti omncane lapho kulayishwa.

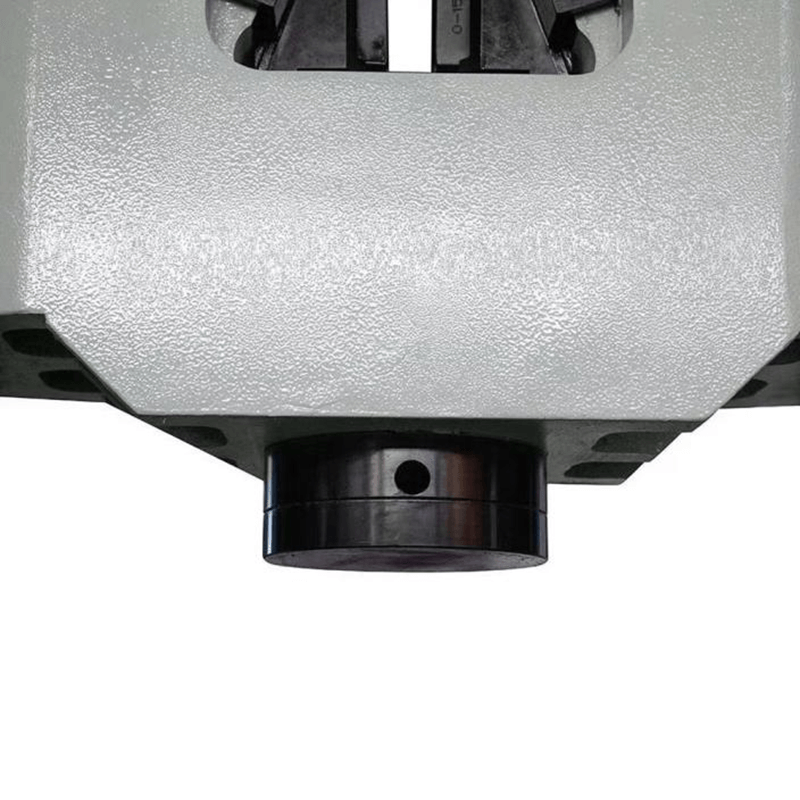

I-4 Middle Beam yamukele indlela eguqukayo yegebe nut Mechanism, isusa igebe futhi ithuthukise ukusebenza kwezilinganiso.

I-5 tank fuel admatic Gap evaliwe, ithuthukisa ukunemba kokulinganisa futhi yandise impilo yenkonzo.

6 Lapho amabutho wokuhlola edlula ama-2% -5% wamandla wokuhlola aphezulu wefayela ngalinye, ukuphepha ngokweqile, kuzoma.

7 Lapho i-piston inyuka endaweni ephezulu yomkhawulo, ukuvikela ukuhamba, motor motor iyoma.

NgokweZinga

Ihlangabezana nezidingo zeNational Standard GB / T228.1-2010 "I-Metal Tensile Test Test egumbini lokushisa", i-GB / T7314-2005 "Amazinga Wokuhlola Ama-Metal. Kungahlangabezana nezidingo zabasebenzisi kanye namazinga anikeziwe.

Isistimu yokuhambisa

Ukuphakamisa nokunciphisa i-crossbeam engezansi kwamukela imoto eqhutshwa yi-reducer, indlela yokuhambisa i-chain, kanye nesikulufo ukubona ukulungiswa kwengxabano nokucindezela isikhala.

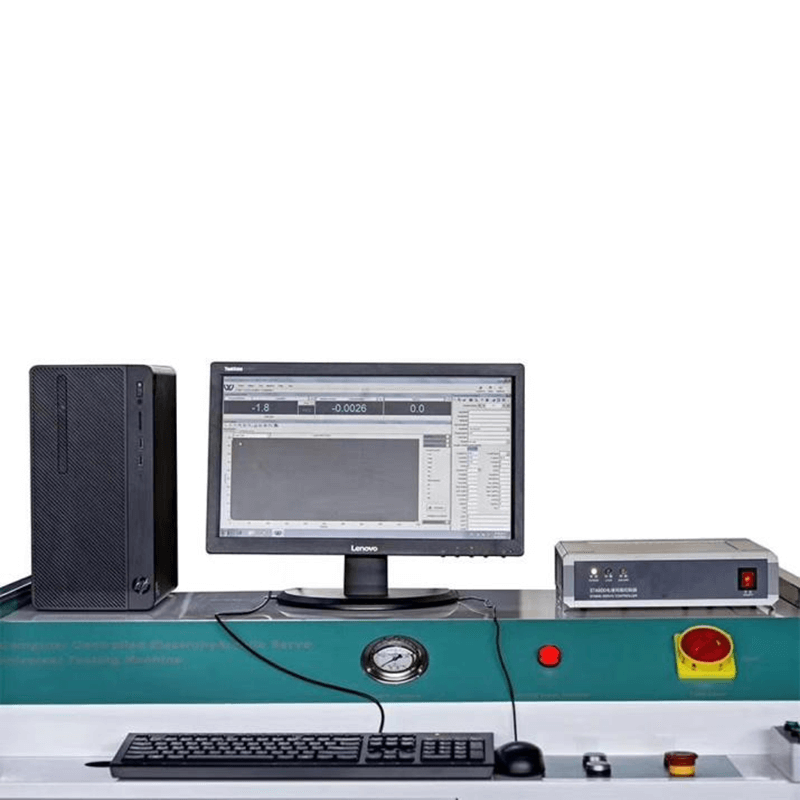

Uhlelo lwe-hydraulic

Amafutha e-hydraulic ethangi likawoyela aqhutshwa yi-motor ukushayela iphampu yengcindezi ephakeme emjikelezweni kawoyela, ugelezela nge-valve ye-valve eyodwa, isihlungi samafutha aphezulu, iqembu le-valve elihlukile, ne-servo Valve, futhi lingena isilinda kawoyela. Ikhompyutha ithumela isibonakaliso sokulawula e-servo valve ukulawula ukuvulwa nokuqondisa kwe-servo valve, ngaleyo ndlela elawula ukugeleza kusilinda, futhi sibona ukulawulwa kwe-velocity test Force kanye nokuhanjiswa okuhlala njalo.

| Isifanekiso | Wew-1000b | Wew-1000d |

| Ukwakheka | 2 Amakholomu | 4 amakholomu |

| 2 Izikulufo | 2 Izikulufo | |

| Max.load Force | I-1000NK | |

| Ibanga lokuhlola | 2% -100% FS | |

| Ukulungiswa kabusha kwesinqumo (MM) | 0.01 | |

| Indlela yokubopha | Ukubopha ngesandla noma i-hydraulic clarking | |

| I-Piston Stroke (ngokwezifiso) (MM) | -Mashumi | |

| Isikhala se-Tensile (MM) | I-670 | |

| Isikhala Sokucindezela (MM) | I-600 | |

| I-Round specimen climpling range (mm) | 13-50 | |

| I-Flat Specimen Calling Range (MM) | 0-50 | |

| Iplate ye-Compression (mm) | Φ0000 | |

Imihlathi eyindilinga: 6-13 / 13- 12-26 / 26-40 / Iyunithi: mm

Imihlathi eyisicaba 0-20 / 20-40 / Iyunithi: mm

Ukuhlanganiswa kwamaphuzu amathathu

Amapuleti we-Compression:

Isikwele 150mm * 150mm

Round 100mm

Round 150mm